您现在的位置是:首页 > Application > Full size inspectionFull size inspection

3D scanning inspection service: exploring quality control innovation in the digital era

![]() 2023-07-06 22:45:24Full size inspection0people have gathered to observe

2023-07-06 22:45:24Full size inspection0people have gathered to observe

IntroductionWith the rapid development of digital technology and the continuous progress of manufacturing, quality control has become crucial in the modern industrial field

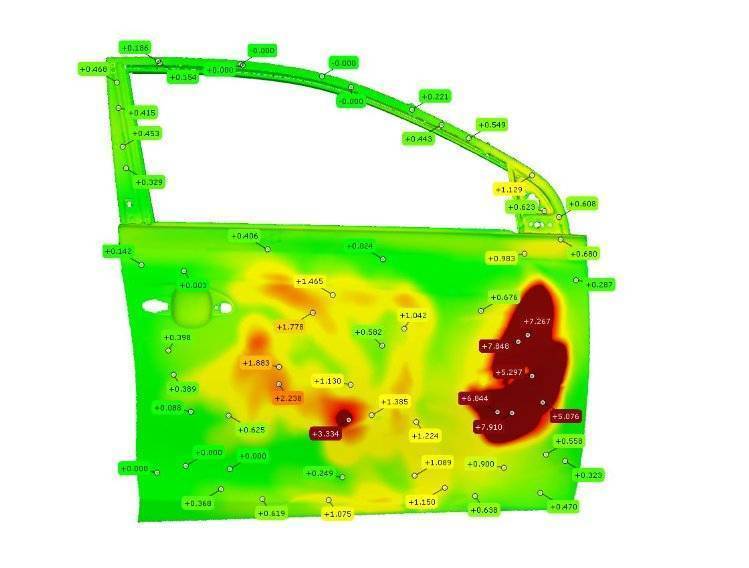

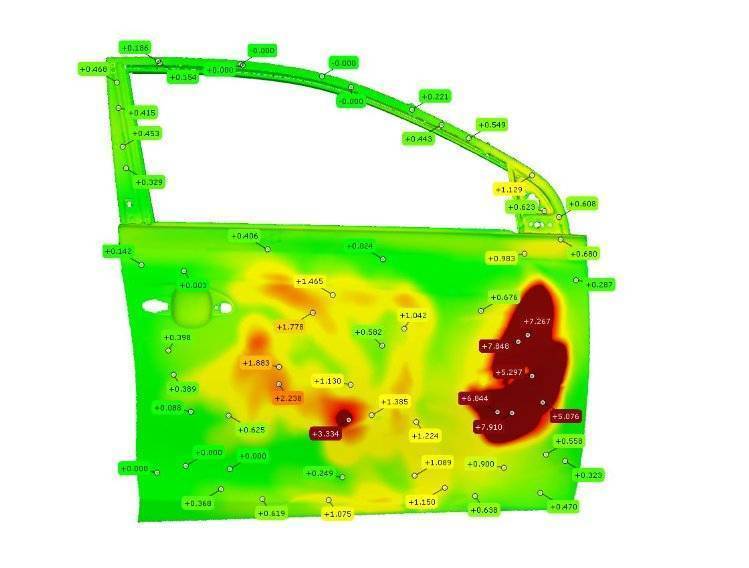

With the rapid development of digital technology and the continuous progress of manufacturing, quality control has become crucial in the modern industrial field. In order to meet high-precision and high-efficiency quality standards, three-dimensional scanning and detection services have emerged. This article will explore the definition, principle, application fields, and innovation brought to the manufacturing industry by 3D scanning inspection services.

Definition and Principles of 3D Scanning and Detection Services

3D scanning detection service is a method based on advanced optical, laser, or other measurement technologies that utilizes high-precision sensors to obtain geometric information of object surfaces and generate digital 3D models. It conducts comprehensive quality inspection and analysis by quickly and accurately capturing the shape, size, and surface features of objects. This service relies on high-precision scanning equipment and complex algorithms, which can provide micrometer level measurement accuracy and high-speed data processing capabilities.

Application Fields of 3D Scanning and Detection Services

3D scanning and detection services have been applied in a wide range of manufacturing industries. In the automotive manufacturing industry, it can be used for component inspection and assembly to ensure the accuracy and quality of products. In the aerospace field, this service can help detect the size and shape of aircraft components to ensure flight safety. In addition, it is also widely used in electronic products, medical devices, engineering construction and other fields for product quality control, prototype development and Reverse engineering.

The Innovative Significance of 3D Scanning and Testing Services

The emergence of 3D scanning inspection services has brought innovative quality control methods to the manufacturing industry. First, it can provide comprehensive and accurate quality data to help manufacturers achieve rapid and accurate product testing. Compared with traditional manual measurement, 3D scanning detection service saves a lot of time and human resources, and reduces the risk of Personal equation. Secondly, it can achieve automated data processing and analysis, quickly identify defects and problems in the product, and adjust the production process in a timely manner to improve product consistency and quality.

Definition and Principles of 3D Scanning and Detection Services

3D scanning detection service is a method based on advanced optical, laser, or other measurement technologies that utilizes high-precision sensors to obtain geometric information of object surfaces and generate digital 3D models. It conducts comprehensive quality inspection and analysis by quickly and accurately capturing the shape, size, and surface features of objects. This service relies on high-precision scanning equipment and complex algorithms, which can provide micrometer level measurement accuracy and high-speed data processing capabilities.

Application Fields of 3D Scanning and Detection Services

3D scanning and detection services have been applied in a wide range of manufacturing industries. In the automotive manufacturing industry, it can be used for component inspection and assembly to ensure the accuracy and quality of products. In the aerospace field, this service can help detect the size and shape of aircraft components to ensure flight safety. In addition, it is also widely used in electronic products, medical devices, engineering construction and other fields for product quality control, prototype development and Reverse engineering.

The Innovative Significance of 3D Scanning and Testing Services

The emergence of 3D scanning inspection services has brought innovative quality control methods to the manufacturing industry. First, it can provide comprehensive and accurate quality data to help manufacturers achieve rapid and accurate product testing. Compared with traditional manual measurement, 3D scanning detection service saves a lot of time and human resources, and reduces the risk of Personal equation. Secondly, it can achieve automated data processing and analysis, quickly identify defects and problems in the product, and adjust the production process in a timely manner to improve product consistency and quality.

Tags: 3D scanning detection service

Great! ()

Previous article:返回列表

Next article:CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

Related articles

- CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

- Full size inspection service

- Full size testing service for product sample verification

- Full size deviation detection service

- 3D scanning inspection service: exploring quality control innovation in the digital era

RandGraph+Text

3D scanning inspection service: exploring quality control innovation in the digital era

With the rapid development of digital technology and the continuous progress of manufacturing, quality control has become crucial in the modern industrial field

Full size inspection service

Full size inspection services are typically used to measure and verify the size and geometric shape of objects or products. This service can play an important r

CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

With the rapid development of technology and the continuous progress of manufacturing, the demand for high-precision and high-efficiency quality control in mode

Full size deviation detection service

Full size deviation detection service is a service that detects and evaluates the size deviation of objects or products. Dimensional deviation refers to the dif

| Notes and comments (There are comments) |

Click Ranking

Full size inspection service

Full size inspection service- Full size inspection service

- Full size deviation detection service

- Full size testing service for product sample verification

- CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

- 3D scanning inspection service: exploring quality control innovation in the digital era

TAGS

Guess you like it

- CAV full size inspection 3D scanning service: technological leap brings new opportunities to the man

- Full size deviation detection service

- Full size testing service for product sample verification

- Full size inspection service

- 3D scanning inspection service: exploring quality control innovation in the digital era